CASTABLE RESINS

Resinify castable resins address the three key needs of jewelry production: ultra-fine detail, clean ash-free burnout, and minimal post-processing. Our castable materials feature stable printing behavior, excellent surface quality, and predictable burnout cycles — producing clean metal parts with no porosity or investment reaction.

CLEANCAST

Castable resin for smooth surfaces and clean burnout

Best for: Small shops, daily jewelry production, fast burnout cycles

CleanCast is a production-ready castable resin designed for everyday jewelry work. It delivers crisp detail, smooth surfaces, and a dependable burnout cycle with minimal ash. Engineered for both small shops and high-volume casting houses, CleanCast prints reliably on all 405 nm DLP and mSLA systems.

Material Properties

| PROPERTY | VALUE |

|---|---|

| Viscosity | ~200 cP @ 30°C |

| Density | ~1.08 g/cm³ |

| Ash Content | 0% (clean burnout) |

| Burnout Temp | 730–780°C |

| Color | Yellow |

JEWELCAST

High-wax feel castable resin for premium detailing

Best for: High-end micro-detail and wax-like surface properties

JewelCast provides a wax-like finish and exceptional fine detail reproduction. Ideal for engagement rings, bridal jewelry, and engraved designs, JewelCast melts out cleanly during burnout and minimizes the need for post-casting cleanup.

Material Properties

| PROPERTY | VALUE |

|---|---|

| Viscosity | ~240 cP @ 30°C |

| Density | 1.10 g/cm³ |

| Wax Content | High (similar to EasyCast 2.0) |

| Burnout Temp | 700–780°C |

| Color | Green |

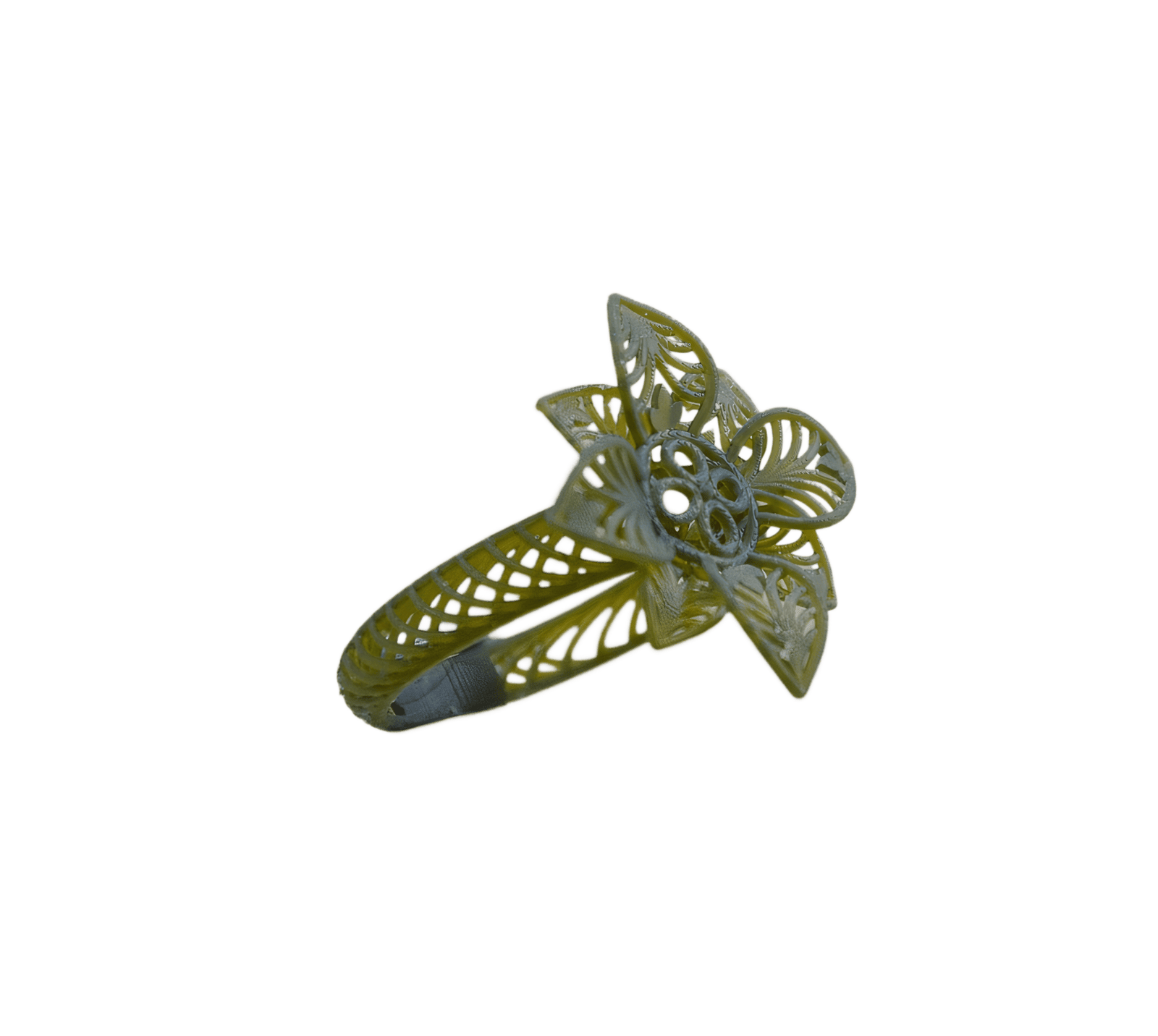

WAXCAST ULTRADETAIL

Nano-filled castable resin for extreme micro-details

Best for: Stone-in-place and pavé setting with extreme detail resolution

WaxCast UltraDetail is designed for pavé stone settings, micro filigree, and ultra-thin features. It burns out cleanly while maintaining dimensional accuracy, making it ideal for high-end jewelers requiring extreme precision.

Material Properties

| PROPERTY | VALUE |

|---|---|

| Detail Resolution | ≤ 0.1 mm |

| Density | 1.12 g/cm³ |

| Elongation | 1–2% (rigid detail resin) |

| Burnout Temp | 720–780°C |

| Color | Amber |

CERAMIXCAST

High-temp master resin for rubber mold making

Best for: Rubber mold masters, high-temp production patterns

CeramixCast is a rigid, ceramic-filled resin optimized for RTV and vulcanized rubber molds. It offers high thermal stability, low shrinkage, and durable surface detail — ideal for mass-production master patterns.

Material Properties

| PROPERTY | VALUE |

|---|---|

| HDT | 200–250°C |

| Viscosity | 300–350 cP |

| Density | 1.30 g/cm³ |

| Shrinkage | Very low |

| Color | Gray |

How Resinify Supports Jewelers & Casting Houses

Resinify’s casting portfolio is designed for jewelers who demand precision and reliability. Our materials burn out cleanly, reproduce micro-details, and are compatible with standard investment casting processes.

We collaborate with jewelry designers and casting houses to fine-tune burnout schedules, improve casting yields, and ensure every pattern prints cleanly with minimal cleanup.

Made in USA

Consistent quality and reliable supply

Clean Burnout

Low ash for smooth cast surfaces

Sharp Detail Reproduction

Ideal for stones-in-place designs, filigree, and micro-pavé