HIGH-TEMPERATURE RESINS

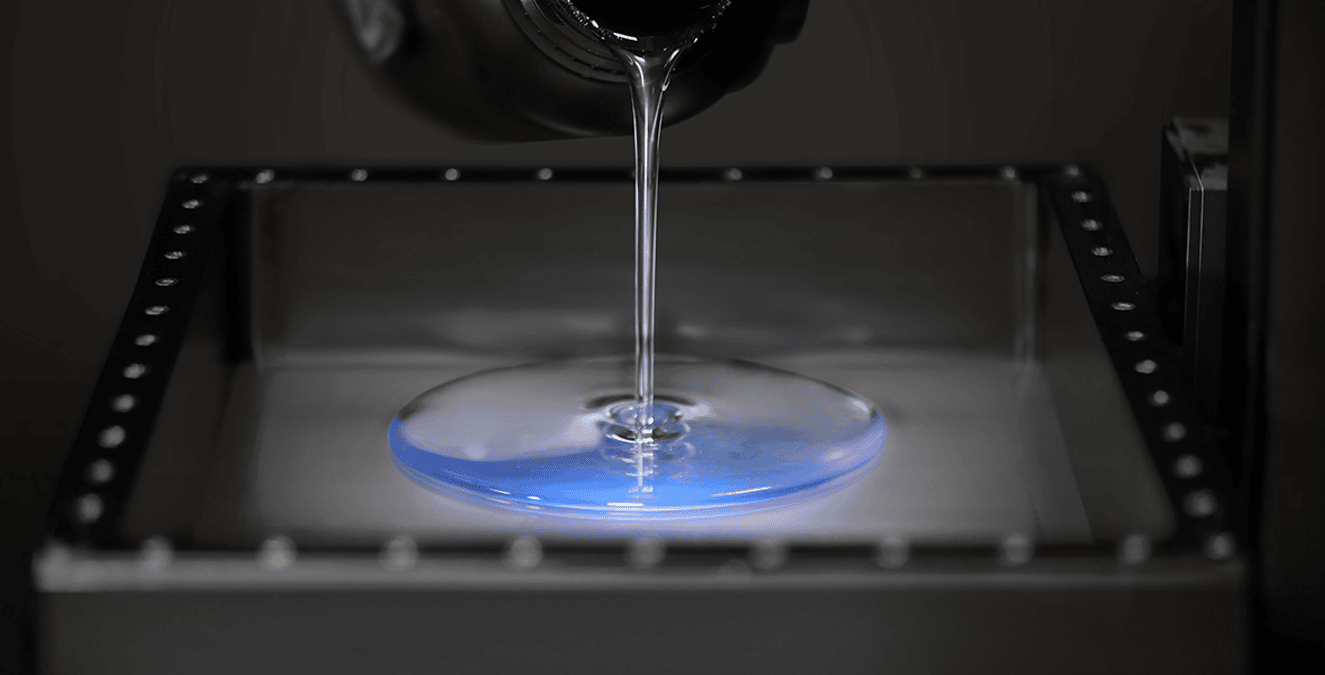

Resinify High-Temperature Resins are formulated for applications requiring extreme thermal stability, dimensional accuracy, and high-performance tooling behavior.

Designed for thermoforming, vulcanizing, injection molding masters, heated fixtures, and high-load engineering environments, these materials offer exceptional heat resistance, stiffness, and long-term durability.

HighTemp™ 150

Industrial high-temperature resin for thermal testing & tooling

Part Number: RT-HT150

Heat-resistant engineering resin designed for functional fixtures, thermoforming tools, and high-load prototypes up to ~150°C.

HighTemp 150 is formulated for stable performance under heat exposure.

It maintains stiffness and dimensional stability during thermal cycling, making it suitable for industrial environments requiring accuracy under elevated temperatures.

Material Properties

| PROPERTY | VALUE |

|---|---|

| Part Number | RT-HT150 |

| Heat Deflection Temp | 150–180°C |

| Tensile Strength | 60–75 MPa |

| Flexural Strength | 90–110 MPa |

| Shore Hardness | 85–90D |

| Shrinkage | Very Low |

| Viscosity | 350–450 cP |

| Color | Light Gray / Natural |

Primary Applications

Thermoforming molds

High-temp functional prototypes

Automotive components exposed to heat

Jigs & fixtures for elevated-temperature processes

Small form tooling

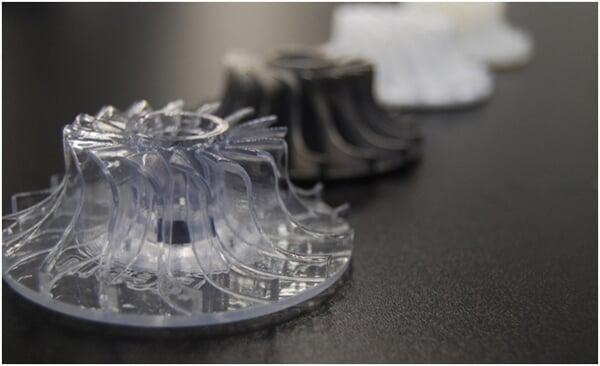

HighTemp™ 230

Extreme high-performance resin for advanced tooling & molding

Part Number: RT-HT230

Ultra high-temperature resin engineered for advanced mold making, vulcanizing, small-batch injection tooling, and applications demanding stability above 200°C.

HighTemp 230 withstands extreme heat cycles and mechanical load without warping.

Ideal for specialized industrial tooling and high-demand engineering applications.

Material Properties

| PROPERTY | VALUE |

|---|---|

| Part Number | RT-HT230 |

| Heat Deflection Temp | 230–260°C |

| Tensile Strength | 70–85 MPa |

| Flexural Modulus | High (stiff composite) |

| Shrinkage | Ultra Low |

| Thermal Stability | Excellent |

| Viscosity | 400–500 cP |

| Color | Beige / Dark Gray |

Primary Applications

Vulcanized rubber molds

Injection mold masters

High-temperature jigs & fixtures

Aerospace & automotive thermal testing

High-load structural prototypes

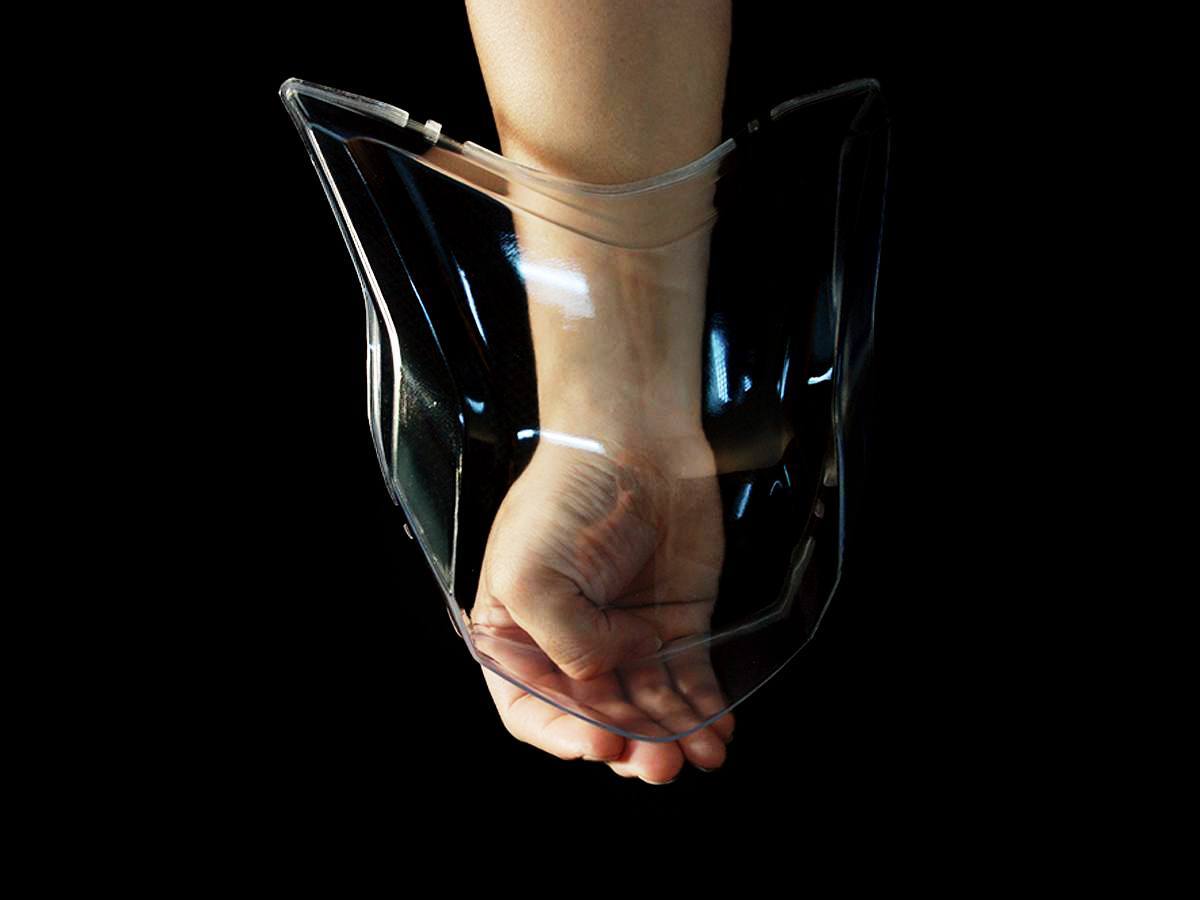

HeatShell™ Pro

High-temp mold resin for dimensional stability & smooth master patterns

Part Number: RT-HT200

Dimensional-stable, high-temperature composite resin optimized for RTV, silicone molds, and master patterns exposed to repeated thermal cycles.

HeatShell Pro offers excellent surface resolution and low shrinkage, producing smooth, detailed master patterns for silicone, urethane, and low-temp injection operations.

Material Properties

| PROPERTY | VALUE |

|---|---|

| Part Number | RT-HT200 |

| Heat Deflection Temp | 200–220°C |

| Surface Detail | Very High |

| Flexural Strength | 90–105 MPa |

| Shrinkage | Very Low |

| Viscosity | 300–350 cP |

| Color | Charcoal Gray |

Primary Applications

RTV & silicone mold masters

Production-ready casting patterns

High-temp production tooling

Smooth master surfaces for replicas

Mold cavities & shells

How Resinify Supports High-Temp Applications

Resinify high-temperature materials deliver:

Heat resistance from 150°C to 260°C

Excellent dimensional stability under load

High stiffness and mechanical strength

Smooth surface detail for tooling and molds

Strong thermal cycle durability

Support for industrial processes like thermoforming, vulcanizing & small-batch molding

Ideal for engineers, mold-makers, industrial manufacturers, and R&D labs.