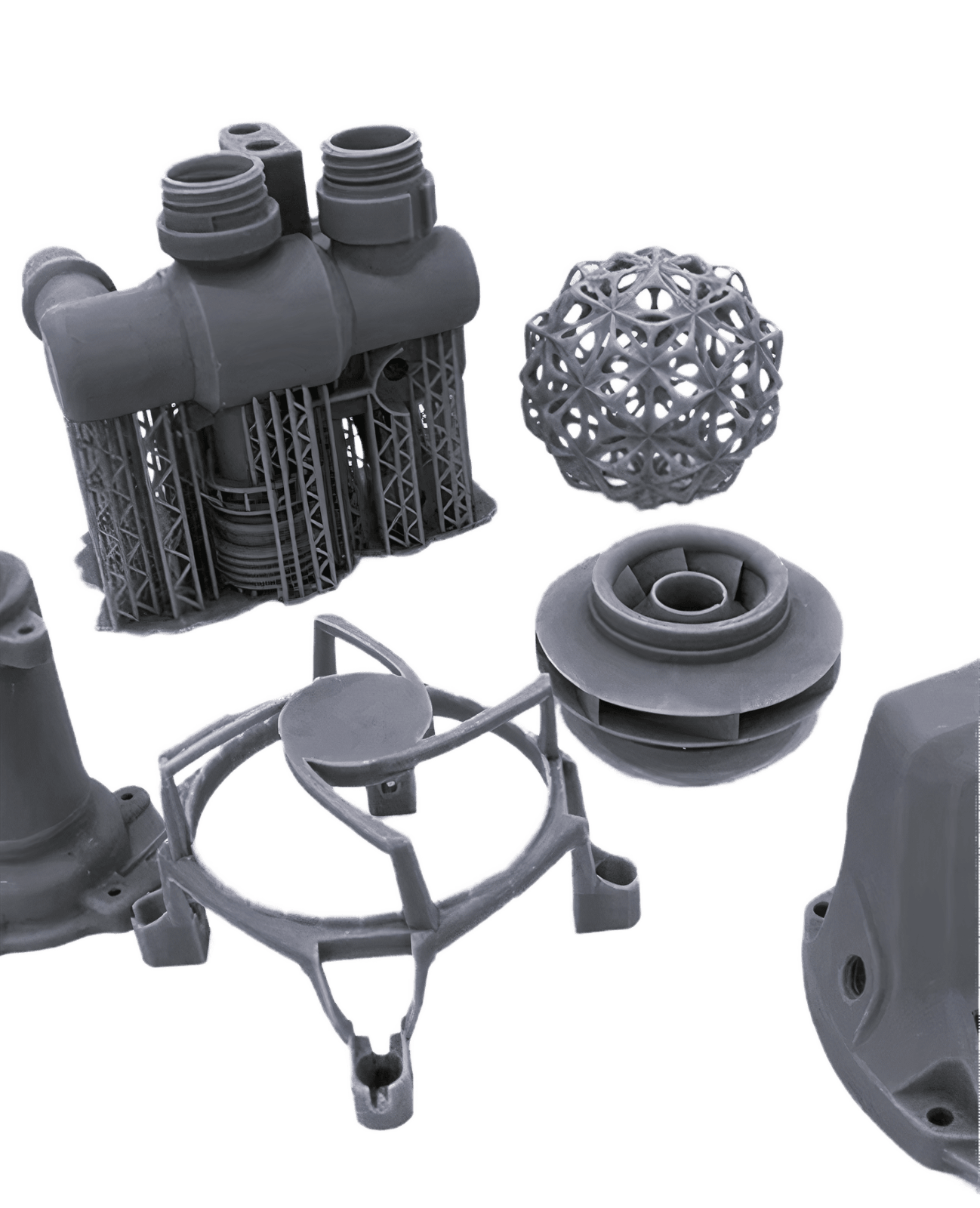

Why 3D Printing for Industrial Production?

Manufacturers need to move from prototype to production faster than ever. Traditional machining and tooling can slow down iterations and add cost, especially for complex or low-volume parts.

High-performance 3D printing resins let teams create jigs, fixtures, housings, and functional components with shorter lead times, less waste, and the flexibility to update designs on the fly.

Faster turnaround for jigs, fixtures, and production aids

Consistent, repeatable accuracy across builds

Reduced tooling and machining costs for small and mid-volume runs

Freedom to design complex internal channels and lightweight lattices

Scalable workflows for both R&D and full production lines

How Resinify Supports Industrial Production Teams

Resinify’s industrial portfolio is formulated for demanding engineering and production environments. Our materials are developed in the U.S.A., tested for strength and stability, and tuned for reliable results on modern DLP and mSLA printers.

We work with manufacturers, service bureaus, and OEM partners to optimize exposure settings, improve mechanical performance, and keep parts easy to wash, cure, and finish. Whether you’re printing a one-off fixture or a full run of functional components, the goal is simple: parts that perform like they belong on the production floor.

Made in USA

Consistent quality and reliable supply

Performance Tested

Formulations targeted for strength, toughness, and stability

Application Support

Help with exposure settings, orientation, and workflows

Resinify Materials for Industrial Production

RigidPro RTV1 —

General Engineering Resin

High-strength rigid material for everyday engineering, prototypes, brackets, and functional assemblies requiring accuracy and stiffness.

ToughMax —

Tough–Flex Hybrid Resin

Hybrid resin balancing toughness and flexibility. Ideal for snap-fits, impact-dampening components, and parts needing both strength and slight flex.

MoldPro —

Tooling & Mold Resin

High-strength, dimensionally stable resin designed for master molds, thermoforming tools, injection test molds, and high-heat industrial applications.

Elastic 40A —

Soft Elastomer Resin

Extremely soft, silicone-like material for seals, damping components, wearable prototypes, and soft-touch surfaces.

NanoCeram —

Ceramic Composite Resin

Ceramic-filled engineering resin with exceptional rigidity, dimensional stability, and resistance to deformation under load.

ToughPro —

High-Impact Tough Resin

Durable, impact-resistant resin designed for jigs, fixtures, tooling aids, and production parts that must withstand stress and repeated use.

HighTemp 150 —

High-Temperature Resin

Engineered for thermal applications with 150–180°C HDT. Ideal for mold tooling, vulcanization, thermoforming, and parts exposed to heat.

FlexPro 80A —

Industrial Flexible Resin

80A Shore hardness elastomer for rubber-like functional parts, gaskets, vibration isolators, grips, and flexible hinges.

CarbonTough —

Carbon Fiber Reinforced Resin

Carbon composite material offering high stiffness, toughness, and lightweight performance. Perfect for mechanical housings and reinforcement structures.

ClearPro —

Optically Clear Resin

Crystal-clear resin for visualization models, fluidics, internal channel inspection, lighting prototypes, and aesthetic transparent parts.